Tšebeletso ea Machining ea CNC

Re le tiisetsa hore ho sa tsotellehe boholo ba mosebetsi, litsebi tsa rona li o nka joalokaha eka ke oa bona. Hape re ka fana ka lits'ebeletso tsa mochini oa CNC tse ka u thusang ho fumana setšoantšo se hlakileng sa sehlahisoa sa ho qetela.

Ke Hobane'ng ha U Re Khetha?

Specialty Integrated Services e ntlafalitse boitsebelo le lits'ebetso tsa eona. Khampani e hlahisa hoo e ka bang likarolo tsohle tsa tšepe tsa maemo a lefatše. Baenjiniere ba rona ba tla sebetsa le uena ho netefatsa boleng bo phahameng ba moralo bakeng sa tlhahiso le kopano. Ts'ebeletso e ntle ea bareki le khotsofalo ke matšoao a k'hamphani ea rona ebile ke motheo oa katleho ea khoebo ea rona.

Ka nako - Rea utloisisa hore likarolo tse ling tsa mosebetsi oa rona li na le nako ea ho qetela e potlakileng, 'me re na le litsebo le mekhoa ea ho netefatsa hore re fana ka nako ka nako ntle le ho senya boleng ba mosebetsi oo re o etsang.

Ba nang le boiphihlelo - esale re fana ka lits'ebeletso tsa milling tsa CNC ka lilemo tse fetang 10. Re bokelletse metjhini e mengata e tsoetseng pele ea ho sila bakeng sa lits'ebetso tse fapaneng mme re na le sehlopha se nang le boiphihlelo sa baenjiniere le basebetsi ho fana ka lihlahisoa tsa boleng bo holimo ho bareki bohle ba rona.

Litšobotsi tsa ho fetoha ha rona ho CNC

1. CNC lathe moralo CAD, moralo moralo modularization

2. Lebelo le phahameng, ho nepahala ho phahameng le ho tšepahala ho phahameng

3. Le hoja thepa ea ho qala hangata e le chitja, e ka ba libopeho tse ling, tse kang sekoere kapa hexagon. Mohala o mong le o mong le boholo bo ka 'na ba hloka "clip" e itseng (subtype ea collet - ho etsa molala ho potoloha ntho).

4. Bolelele ba bar bo ka fapana ho itšetlehile ka lijo tsa bar.

5. Lisebelisoa tsa li-lathe tsa CNC kapa li-turning centers li kenngoa ho turret e laoloang ke k'homphieutha.

6. Qoba libopeho tse thata tse kang tse telele haholo tse tšesaane

Kalafo ea Bokaholimo

- Kalafo ea Mechanical Surface Ho phatloha ha lehlabathe, ho Thunya ho Thunya, Ho Tula, Ho bilika, ho bentša, ho Hlōla borashe, Ho fafatsa, ho penta, ho penta ka oli joalo-joalo.

- Kalafo ea Lik'hemik'hale tsa Bolulo le ho Blackening, Phosphating, Pickling, Electroless Plating ea Metals le Alloys tse sa tšoaneng joalo-joalo.

- Electrochemical Surface Treatment Anodic Oxidation, Electrochemical Polishing, Electroplating joalo-joalo.

- Phekolo ea Sejoale-joale ea Surface CVD, PVD, ho kenngoa ha Ion, Plating ea Ion, Phekolo ea Laser Surface ect.

- Ho phatloha ha Lehlabathe le Omeletseng, ho phatloha ha lehlabathe le metsi, ho phatloha ha lehlabathe la Atomized joalo-joalo.

- Ho fafatsa ka Electrostatic Spraying, Fame Spraying, Powder Spraying, Plastic Spraying, Plasma Spraying.

- Electroplating Copper Plating, Chromium Plating, Zinc Plating, Nickel Plating

R&D

Re na le boiphihlelo bo fetang lilemo tse leshome ho moralo oa 3D. Sehlopha sa rona se sebetsa le bareki ho hlahisa meralo / likarolo tse fihlelang litlhoko tsa bona, ha re ntse re nahana ka litšenyehelo, boima le mekhoa ea tlhahiso.

Ka mor'a hore moralo o phethoe, re theha mokhoa oohle oa boenjiniere le tlhahiso ea sesebelisoa. 'Me re ka qala teko e latelang feela ka mor'a hore lefapha la boleng le amohele sesebelisoa.

Re tsepamisa maikutlo lits'ebetsong tsena tsa mantlha ts'ebetsong ea R&D:

- Moqapi oa likarolo

- Sesebelisoa DFM

- Moqapi oa lisebelisoa / hlobo

- Mold Flow – Ketsiso

- Ho taka

- CAM

- CNC Machining

Kopo

CNC Machining ea rona, prototype e potlakileng le tlhahiso e tlase ea Volume e loketseng indasteri e mengata joalo ka Likoloi, Lithuthuthu, Mechini, Lifofane, terene ea likulo, Libaesekele, Metsi, Elektronike, Thepa ea Saense, Theatre ea Laser, Liroboto, Sistimi ea Taolo ea Oli le Khase, Lisebelisoa tsa bongaka. , lisebelisoa tse amohelang mats'oao, Lisebelisoa tsa Optical, Khamera & Foto, Thepa ea lipapali Botle, Leseli,

-

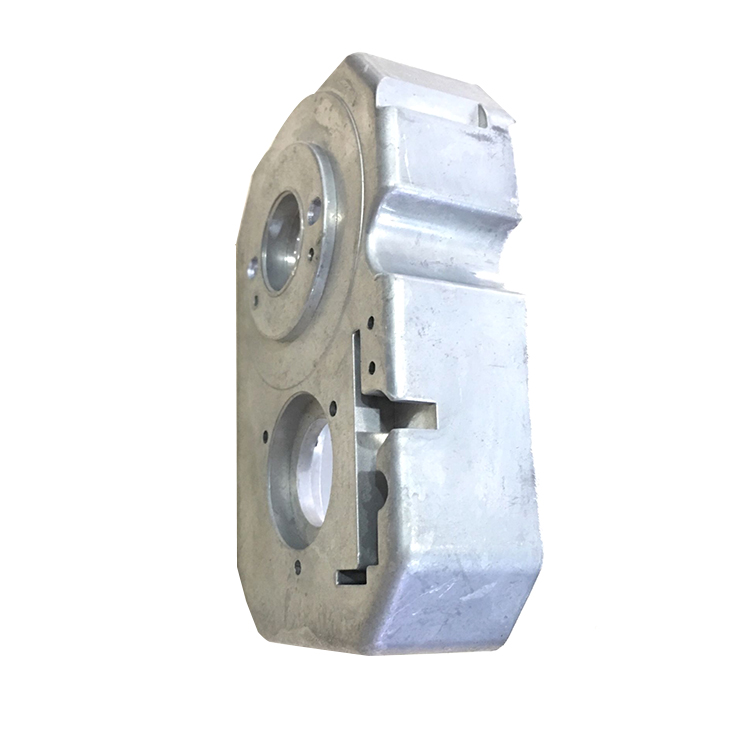

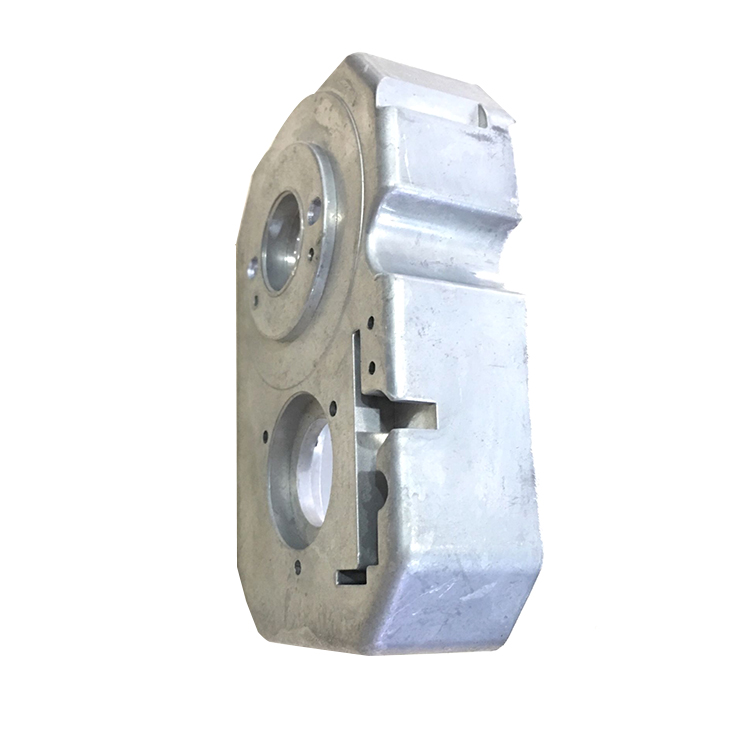

Custom Aluminium Alloy Die Casting Auto Spare

-

Hub ea lebili le ka pele la sethuthuthu Bakeng sa BAJAJ BM150, WAVE...

-

Re ka etsa Aluminium Alloy/Magnesium Alloy/Zinc...

-

Aluminium die casting OEM customized cast aluminium ...

-

Fektheri OEM tšepe karolo tloaelo aluminium die casting

-

Karolo ea Bongaka ea Precision Steel Plastic...